Manufacturing Sector

1992-2017

These are our choices for 25 of the biggest buffalo announcements made in the South in the 25 years since Southern Business & Development has been published. These aren’t necessarily the largest projects announced in the last 25 years, but they are to us the most important for the economies they have transformed.

There are certainly other manufacturing projects that have continued to transform parts of the South that were announced prior to the magazine’s founding. But we thought we would simply profile some of the largest big buffaloes that SB&D covered over the last 25 years and give you some data, such as employment and the estimated annual payroll these facilities produce. The big buffaloes are listed in chronological order.

BMW Spartanburg County, S.C.

Announced the same year as SB&D’s founding, BMW was the first European carmaker to build an assembly plant in the South. Japanese automakers were already operating in Kentucky and Tennessee, but BMW’s South Carolina plant paved the way for many more foreign automakers in the Southern Automotive Corridor, including Mercedes-Benz the next year.

Announced the same year as SB&D’s founding, BMW was the first European carmaker to build an assembly plant in the South. Japanese automakers were already operating in Kentucky and Tennessee, but BMW’s South Carolina plant paved the way for many more foreign automakers in the Southern Automotive Corridor, including Mercedes-Benz the next year.

Employees: Nearly 10,000

Estimated 2016 Payroll: $745 million

Factoid: About 70 percent of all vehicles made at BMW’s South Carolina plant are exported to more than 140 countries each year through the Port of Charleston.

Economies Transformed: All of South Carolina, particularly the Upstate, including Spartanburg, Greenville, Anderson and Laurens counties.

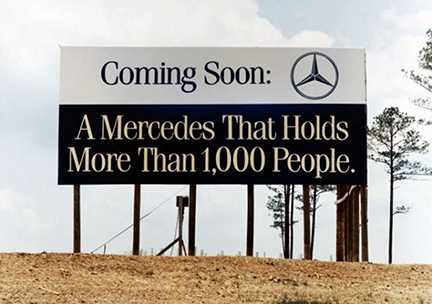

Mercedes-Benz Tuscaloosa County, Ala.

Following BMW’s plant announcement the year before, fellow German automaker Mercedes-Benz shocked the world by choosing a site in Tuscaloosa, Ala., for its first North American assembly facility. The company makes SUVs and sedans at the plant.

Following BMW’s plant announcement the year before, fellow German automaker Mercedes-Benz shocked the world by choosing a site in Tuscaloosa, Ala., for its first North American assembly facility. The company makes SUVs and sedans at the plant.

Employees: About 4,000

Estimated 2016 Payroll: $435 million

Factoid: The current average hourly wage at the Mercedes plant in Alabama is $65 an hour, one of the highest average wages of any assembly plant in North America.

Economies Transformed: The entire state of Alabama, specifically Tuscaloosa and Jefferson counties. Cullman and Walker counties have also benefited greatly.

Lockheed Martin Fort Worth, Texas

Lockheed Martin officially took over the Air Force Plant 4 in Fort Worth in 1993, even though military aircraft have been assembled at the facility since 1942. Lockheed fully assembles the F-35 and F-16 fighter jets there. The company has ramped up production of the F-35 and expects to hire another 2,000 workers at the facility by the end of this year. In 2016, Lockheed built about 50 F-35s, and plans call for production to increase to about 160 a year by 2019.

Lockheed Martin officially took over the Air Force Plant 4 in Fort Worth in 1993, even though military aircraft have been assembled at the facility since 1942. Lockheed fully assembles the F-35 and F-16 fighter jets there. The company has ramped up production of the F-35 and expects to hire another 2,000 workers at the facility by the end of this year. In 2016, Lockheed built about 50 F-35s, and plans call for production to increase to about 160 a year by 2019.

Employees: Almost 15,000

Estimated 2016 Payroll: $1.6 billion

Factoid: Air Force Plant 4 encompasses 4.9 million square feet with an assembly bay that is nearly a mile long.

Economies Transformed: Dallas-Fort Worth and much of North Texas.

Metalsa Elizabethtown, Ky.

Metalsa is a Mexican global company with more than 60 years experience in the automotive industry. It purchased the Elizabethtown, Ky., plant in March 2010 from Dana, along with nine other plants Dana owned. Metalsa produces vehicle frames, chassis parts, engine cradles and suspension components at the Elizabethtown plant for a variety of customers, including the GM and Toyota plants in Kentucky.

Metalsa is a Mexican global company with more than 60 years experience in the automotive industry. It purchased the Elizabethtown, Ky., plant in March 2010 from Dana, along with nine other plants Dana owned. Metalsa produces vehicle frames, chassis parts, engine cradles and suspension components at the Elizabethtown plant for a variety of customers, including the GM and Toyota plants in Kentucky.

Employees: 1,727

Estimated 2016 Payroll: $108 million

Factoid: Metalsa is Mexico’s largest vehicle frame and structures supplier with 10 facilities in the U.S., Argentina, Australia, Venezuela and Brazil.

Economies Transformed: Hardin County and several counties in Central Kentucky.

Toyota Buffalo, W.Va.

.jpg) Toyota currently produces 650,000 engines and 740,000 transmissions annually for the Camry, Corolla, Avalon, Lexus RX 350, Sienna, Highlander and RAV4 models that are assembled all over North America. Toyota has expanded its 1.9 million-square-foot West Virginia plant eight times in two decades and has invested nearly $2 billion into the facility.

Toyota currently produces 650,000 engines and 740,000 transmissions annually for the Camry, Corolla, Avalon, Lexus RX 350, Sienna, Highlander and RAV4 models that are assembled all over North America. Toyota has expanded its 1.9 million-square-foot West Virginia plant eight times in two decades and has invested nearly $2 billion into the facility.

Employees: About 1,600

Estimated 2016 Payroll: $93 million

Factoid: When Toyota first opened its West Virginia operations in 1997, 19,000 people applied for the 300 initial job openings.

Economies Transformed: Virtually the entire state, specifically Huntington and Charleston.

Nissan Decherd, Tenn.

Nissan Powertrain in rural Decherd, Tenn., has been making engines for the company’s assembly plants in Canton, Miss., and Smyrna, Tenn., since 1997. In 2013, the plant began supplying electric motors to support U.S. production of the all-electric Nissan LEAF that is assembled in Tennessee. The factory is also a supplier of engines to European versions of the Infiniti Q50 sports sedan and the Mercedes-Benz C-Class assembled in Vance, Ala. Nissan has invested more than $1 billion in the 1.1 million-square-foot facility that makes one new engine every 19 seconds.

Nissan Powertrain in rural Decherd, Tenn., has been making engines for the company’s assembly plants in Canton, Miss., and Smyrna, Tenn., since 1997. In 2013, the plant began supplying electric motors to support U.S. production of the all-electric Nissan LEAF that is assembled in Tennessee. The factory is also a supplier of engines to European versions of the Infiniti Q50 sports sedan and the Mercedes-Benz C-Class assembled in Vance, Ala. Nissan has invested more than $1 billion in the 1.1 million-square-foot facility that makes one new engine every 19 seconds.

Employees: About 1,700

Estimated 2016 Payroll: $75 million

Factoid: The Infiniti Decherd Powertrain Plant is a collaboration between Renault-Nissan and Daimler AG. Construction began on the $319 million, 310,000-square-foot facility that produces engines for the Infiniti Q50 and the Mercedes C-Class that is now built in Alabama.

Economies Transformed: Much of rural South Central Tennessee and Northern Alabama.

Samsung Austin, Texas

Samsung Austin is one of the few survivors of the mid-1990s semiconductor craze when every county in the South thought it had a chance to land a chip plant. Most of those facilities are now closed, but not Samsung in Austin. The South Korean company continues to invest billions into its Texas facility.

Samsung Austin is one of the few survivors of the mid-1990s semiconductor craze when every county in the South thought it had a chance to land a chip plant. Most of those facilities are now closed, but not Samsung in Austin. The South Korean company continues to invest billions into its Texas facility.

Employees: About 3,200

Estimated 2016 Payroll: $290 million

Factoid: Samsung has invested more than $16 billion in its Austin facility since its establishment in 1997.

Economies Transformed: Austin, Central Texas.

Honda Timmonsville, S.C.

There are larger projects we could have put on this list than Honda’s ATV plant near Florence, S.C., but this deal was highly sought after back in the day. The company has produced over 3 million ATVs and SxS vehicles since production began in 1998. Honda also builds about 310,000 engines each year on site.

There are larger projects we could have put on this list than Honda’s ATV plant near Florence, S.C., but this deal was highly sought after back in the day. The company has produced over 3 million ATVs and SxS vehicles since production began in 1998. Honda also builds about 310,000 engines each year on site.

Employees: About 1,000

Estimated 2016 Payroll: $65 million

Factoid: In 2015, Honda South Carolina won the South Carolina Manufacturing Excellence Award and celebrated 3 million hours with no lost time at the plant.

Economies Transformed: Florence and Darlington counties in South Carolina.

Bridgestone Aiken, S.C.

Bridgestone operates two plants in Aiken County, one that makes passenger tires and another that produces off-road radial tires. Recently, a $1.2 billion expansion was approved for Asia, but Bridgestone officials decided to expand in Aiken County as opposed to offshore.

Bridgestone operates two plants in Aiken County, one that makes passenger tires and another that produces off-road radial tires. Recently, a $1.2 billion expansion was approved for Asia, but Bridgestone officials decided to expand in Aiken County as opposed to offshore.

Employees: About 1,800

Estimated 2016 Payroll: $135 million

Factoid: In 2011, Bridgestone announced it would construct the off-road tire facility and expand its existing passenger tire facility with an investment of $1.2 billion. At the time, it was the largest initial capital investment by a company in South Carolina history.

Economies Transformed: Western South Carolina, including Aiken, Saluda and Edgefield counties, as well as Augusta, Ga.

Honda Talladega County, Ala.

Honda Manufacturing of Alabama announced its $2 billion Lincoln, Ala., plant in 1999 and production began on November 14, 2001. The 3.7-million-square-foot plant built on 1,350 acres is the first Honda factory to have both engine production and vehicle assembly on site.

Honda Manufacturing of Alabama announced its $2 billion Lincoln, Ala., plant in 1999 and production began on November 14, 2001. The 3.7-million-square-foot plant built on 1,350 acres is the first Honda factory to have both engine production and vehicle assembly on site.

Employees: About 5,000

Estimated 2016 Payroll: $370 million

Factoid: Less than a year into production, Honda announced it would expand the Alabama plant by injecting $425 million. The addition of a second line increased employment by 2,000 and increased annual production by 300,000 vehicles and V-6 engines.

Economies Transformed: Much of Eastern Alabama.

Austal Mobile, Ala.

Austal USA is the American subsidiary of Australian shipbuilder Austal. The company started operations in 1999 with under 100 employees on a 14-acre facility that consisted of a 90-by-60 assembly bay fronted by a 380-foot wharf on the Mobile River in downtown Mobile, Ala. The first major expansion was completed in November 2005, shortly after Austal began designing the Independence-variant Littoral Combat Ship for the U.S. Navy. Today, Austal’s $400 million ship manufacturing facility encompasses 164 acres and houses over 4,000 workers.

Austal USA is the American subsidiary of Australian shipbuilder Austal. The company started operations in 1999 with under 100 employees on a 14-acre facility that consisted of a 90-by-60 assembly bay fronted by a 380-foot wharf on the Mobile River in downtown Mobile, Ala. The first major expansion was completed in November 2005, shortly after Austal began designing the Independence-variant Littoral Combat Ship for the U.S. Navy. Today, Austal’s $400 million ship manufacturing facility encompasses 164 acres and houses over 4,000 workers.

Employees: About 4,200

Estimated 2016 Payroll: $277 million

Factoid: At any one time, there are usually at least six Littoral Combat Ships under various stages of construction simultaneously at Austal’s Mobile, Ala., manufacturing facility. The LCS is the most advanced high-speed military craft in the world. The congressional cost cap is $584 million per ship, and Austal has been awarded 30 LCSs by the Navy.

Economies Transformed: Much of South Alabama, including Mobile and Baldwin counties.

Nissan Canton, Miss.

The opening of the Nissan Canton Vehicle Assembly Plant in 2003 was a groundbreaking moment, bringing automotive production to Mississippi for the first time. The plant assembles a variety of vehicles including cars, trucks and SUVs. Nissan Canton generated $2.6 billion in disposable incomes in 2016.

The opening of the Nissan Canton Vehicle Assembly Plant in 2003 was a groundbreaking moment, bringing automotive production to Mississippi for the first time. The plant assembles a variety of vehicles including cars, trucks and SUVs. Nissan Canton generated $2.6 billion in disposable incomes in 2016.

Employees: About 6,500

Estimated 2016 Payroll: $390 million

Factoid: The workforce at Nissan in Canton comes from all over the state of Mississippi with employees from 61 of the 82 counties.

Economies Transformed: Entire state of Mississippi, Madison County and Jackson, Miss. Madison County, home of Nissan, has the highest median family income in the state.

Toyota Huntsville, Ala.

While Alabama is not home to a Toyota assembly facility, it is home to one of the Japanese automaker’s engine plants. Toyota Alabama is a nearly $1 billion facility that makes engines for the Camry, RAV4, Highlander, Tacoma, Tundra and Sequoia models. That means the plant makes engines for Toyota’s assembly plants in Indiana, Kentucky and Texas. The plant made over 700,000 engines in 2016.

While Alabama is not home to a Toyota assembly facility, it is home to one of the Japanese automaker’s engine plants. Toyota Alabama is a nearly $1 billion facility that makes engines for the Camry, RAV4, Highlander, Tacoma, Tundra and Sequoia models. That means the plant makes engines for Toyota’s assembly plants in Indiana, Kentucky and Texas. The plant made over 700,000 engines in 2016.

Employees: About 1,500

Estimated 2016 Payroll: $100 million

Factoid: Toyota’s plant in Huntsville, Ala., is the only Toyota plant that produces four-cylinder, V6 and V8 engines under one roof.

Economies Transformed: Much of North Alabama, including the Huntsville and Decatur areas.

Hyundai Montgomery, Ala.

Hyundai Motor Manufacturing Alabama (HMMA) is the first automotive assembly facility built by the South Korea automaker in the United States. The plant has an annual capacity of 400,000 vehicles and 700,000 engines. Hyundai has invested $1.7 billion in the 3.2-million-square-foot facility that sits on 1,744 acres directly on Interstate 65 just south of downtown Montgomery.

Hyundai Motor Manufacturing Alabama (HMMA) is the first automotive assembly facility built by the South Korea automaker in the United States. The plant has an annual capacity of 400,000 vehicles and 700,000 engines. Hyundai has invested $1.7 billion in the 3.2-million-square-foot facility that sits on 1,744 acres directly on Interstate 65 just south of downtown Montgomery.

Employees: About 3,100

Estimated 2016 Payroll: $245 million

Factoid: Alabama captured Hyundai with a $253 million incentive package, just edging out Kentucky, which offered the automaker the Glendale megasite in Hardin County, Ky.

Economies Transformed: Central, Southeast Alabama and Montgomery County. Tallapoosa and Lee counties have benefited as well.

Cheniere Energy Cameron Parish, La.

This big buffalo doesn’t have the employees its other 24 do, but it has single-handedly transformed the economy of Southwest Louisiana. The $20 billion liquefied natural gas export facility in Cameron Parish is one of the most expensive projects ever built in the South. In fact, it is the first large-scale LNG export facility ever constructed in North America and the first built in over 40 years. The LNG export facility is a testament to the fracking frenzy that has set the U.S. on course for energy independence.

This big buffalo doesn’t have the employees its other 24 do, but it has single-handedly transformed the economy of Southwest Louisiana. The $20 billion liquefied natural gas export facility in Cameron Parish is one of the most expensive projects ever built in the South. In fact, it is the first large-scale LNG export facility ever constructed in North America and the first built in over 40 years. The LNG export facility is a testament to the fracking frenzy that has set the U.S. on course for energy independence.

Employees: About 400 (4,500 temporary construction jobs)

Estimated 2016 Payroll: $42 million

Factoid: Houston-based Cheniere Energy originally built an LNG import facility on the Sabine Pass site on the border of Louisiana and Texas at a cost of billions. Advanced drilling technologies were implemented over the last decade and the U.S. found itself with a glut of natural gas. As a result, Cheniere turned the LNG import facility into an export facility. The company began LNG exports in early 2017.

Economies Transformed: Southwest Louisiana and Southeast Texas, specifically Lake Charles and Port Arthur.

Toyota San Antonio, Texas

In 2002 and 2003, Toyota officials were looking to add pickup truck capacity in the U.S. Their site teams wanted to place the new plant somewhere in the traditional Southern Auto Corridor (Interstate 65 is the spine). But the marketing department wanted the plant located in Texas, the largest pickup truck sub-market in the world. Texas won out, as a site in the South Side of San Antonio was chosen.

In 2002 and 2003, Toyota officials were looking to add pickup truck capacity in the U.S. Their site teams wanted to place the new plant somewhere in the traditional Southern Auto Corridor (Interstate 65 is the spine). But the marketing department wanted the plant located in Texas, the largest pickup truck sub-market in the world. Texas won out, as a site in the South Side of San Antonio was chosen.

Employees: About 2,800

Estimated 2016 Payroll: $182 million

Factoid: There were no existing parts suppliers in the San Antonio region when Toyota decided to locate a plant there. So, the Japanese automaker developed a supplier park on site, where about 2,800 additional workers are housed.

Economies Transformed: San Antonio and South Texas.

DENSO Athens, Tenn.

DENSO Manufacturing Athens Tennessee Inc. (DNAT) includes three production facilities on 138 acres. The plant manufactures ignition and exhaust systems and gasoline delivery systems for its global customers, which include Lexus, Hyundai, GM, Volvo, Ford, Mazda, Honda and Nissan. DENSO operates 18 facilities in the Southern Auto Corridor, and its plant in Athens, Tenn., is not the largest. The DENSO facility up the Interstate in Maryville, Tenn., houses more than 4,000 workers, but it was announced prior to 1992, so it isn’t eligible for this listing of big buffaloes.

DENSO Manufacturing Athens Tennessee Inc. (DNAT) includes three production facilities on 138 acres. The plant manufactures ignition and exhaust systems and gasoline delivery systems for its global customers, which include Lexus, Hyundai, GM, Volvo, Ford, Mazda, Honda and Nissan. DENSO operates 18 facilities in the Southern Auto Corridor, and its plant in Athens, Tenn., is not the largest. The DENSO facility up the Interstate in Maryville, Tenn., houses more than 4,000 workers, but it was announced prior to 1992, so it isn’t eligible for this listing of big buffaloes.

Employees: 1,393

Estimated 2016 Payroll: $85 million

Factoid: DENSO created the 11.5-acre DENSO EcoPark, located next to the complex of plants. The park, built in partnership with the City of Athens, provides a safe place for the community to walk and be immersed in nature.

Economies Transformed: Athens, Tenn., including McMinn, Loudoun, Meigs and Bradley counties.

Kia West Point, Ga.

Hyundai cousin Kia Motors announced it would build its first U.S. plant near the Alabama-Georgia border in West Georgia, only 80 miles from the Hyundai plant in Montgomery, Ala., a little over 10 years ago. The first vehicle, a Kia Sorento, rolled off the line in November of 2009. Both plants and Korean automakers enjoy a symbiotic relationship sharing dozens of suppliers located in Alabama and Georgia. Kia’s engines are built by Hyundai in Alabama and Hyundai’s transmissions are built by Kia in Georgia. Both plants were running three shifts a day for a while during the recovery, but that is no longer the case.

Hyundai cousin Kia Motors announced it would build its first U.S. plant near the Alabama-Georgia border in West Georgia, only 80 miles from the Hyundai plant in Montgomery, Ala., a little over 10 years ago. The first vehicle, a Kia Sorento, rolled off the line in November of 2009. Both plants and Korean automakers enjoy a symbiotic relationship sharing dozens of suppliers located in Alabama and Georgia. Kia’s engines are built by Hyundai in Alabama and Hyundai’s transmissions are built by Kia in Georgia. Both plants were running three shifts a day for a while during the recovery, but that is no longer the case.

Employees: About 3,100

Estimated 2016 Payroll: $245 million

Factoid: A Kia executive found the 2,200-acre site in West Point, Ga., while driving to the Hyundai plant in Montgomery from Atlanta. But prior to that, SB&D publisher Michael Randle had uncovered that Kia’s negotiations with Mississippi had ended badly. He then put his finger on a map on Interstate 85 from Montgomery to Georgia and saw that Troup County was the first location in Georgia. He called Jane Fryer, the economic development director at the time in Troup County and asked her if she had any contact with Kia. Jane told him no. Randle said, “Well, Jane, you are about to.”

Economies Transformed: Much of West Georgia and East Alabama, particularly Troup, Meriwether and Harris counties in Georgia, and Lee and Chambers counties in Alabama.

Toyota Blue Springs, Miss.

Toyota announced its third assembly plant in the South in 2007, but didn’t begin assembly of its first vehicle until the fall of 2011. Originally, the plant was built to assemble the Highlander SUV model. The Great Recession and $4-a-gallon gas prices in 2008 nixed the SUV plans and the plant was delayed. Once the recession ended, Toyota officials decided to bring production of the Corolla sedan to the plant in Blue Springs, Miss.

Toyota announced its third assembly plant in the South in 2007, but didn’t begin assembly of its first vehicle until the fall of 2011. Originally, the plant was built to assemble the Highlander SUV model. The Great Recession and $4-a-gallon gas prices in 2008 nixed the SUV plans and the plant was delayed. Once the recession ended, Toyota officials decided to bring production of the Corolla sedan to the plant in Blue Springs, Miss.

Employees: About 2,000

Estimated 2016 Payroll: $130 million

Factoid: Toyota’s Mississippi assembly plant is the only one in the Southern Automotive Corridor that produces a single model. All of the other plants in the South produce two or more models. After the decision was made not to produce the Highlander SUV, Toyota announced it would build the Prius model before finally deciding on the Corolla.

Economies Transformed: Northeast Mississippi, specifically Union, Lee and Pontotoc counties.

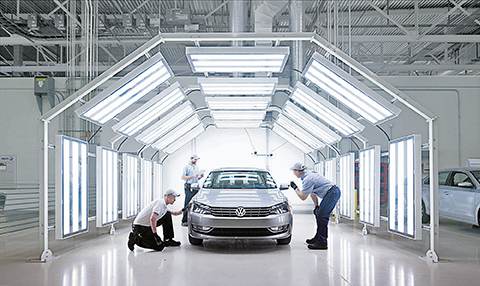

Volkswagen Chattanooga, Tenn.

Volkswagen briefly built vehicles in the U.S. at a plant in Pennsylvania between 1978 and 1987. That plant was successful at first, but labor union unrest ultimately forced VW to close the factory. Volkswagen’s second U.S. plant, built at a former ammunition facility in Chattanooga, has also had its labor union issues, however that seems to have calmed down of late. Volkswagen produces two models — a sedan and a large SUV — at the Tennessee plant and will add a small SUV to the mix next year.

Volkswagen briefly built vehicles in the U.S. at a plant in Pennsylvania between 1978 and 1987. That plant was successful at first, but labor union unrest ultimately forced VW to close the factory. Volkswagen’s second U.S. plant, built at a former ammunition facility in Chattanooga, has also had its labor union issues, however that seems to have calmed down of late. Volkswagen produces two models — a sedan and a large SUV — at the Tennessee plant and will add a small SUV to the mix next year.

Employees: About 3,500

Estimated 2016 Payroll: $265 million

Factoid: Volkswagen’s Chattanooga plant is one of the most sustainable in the world with a solar park on site powering the plant. The reuse of rainwater on the site saves up to 350,000 gallons of water per month. The factory is the first and only LEED Platinum certified automotive plant in the world.

Economies Transformed: Much of the Chattanooga region, including Hamilton and Bradley counties. Some of Northwest Georgia has benefited as well.

Engineered Floors Whitfield County, Ga.

Engineered Floors was started by Bob Shaw eight years after his former company Shaw Industries was sold to Berkshire Hathaway in 2001. The company has grown rapidly in a very short period of time, essentially transforming Northwest Georgia’s economy. The region, particularly Dalton and Whitfield County, Ga., is the flooring capital of the world, and was slammed during the recession when the unemployment rate topped 14 percent. Today, the unemployment rate in Dalton is 5.2 percent, thanks in large part to Engineered Floors. The company will soon have 4 million square feet of manufacturing space in Northwest Georgia. One of its plants in Dalton is currently expanding for a total of 2.7 million square feet and 3,000 employees. It is the largest manufacturing plant under one roof in the Southeast.

Engineered Floors was started by Bob Shaw eight years after his former company Shaw Industries was sold to Berkshire Hathaway in 2001. The company has grown rapidly in a very short period of time, essentially transforming Northwest Georgia’s economy. The region, particularly Dalton and Whitfield County, Ga., is the flooring capital of the world, and was slammed during the recession when the unemployment rate topped 14 percent. Today, the unemployment rate in Dalton is 5.2 percent, thanks in large part to Engineered Floors. The company will soon have 4 million square feet of manufacturing space in Northwest Georgia. One of its plants in Dalton is currently expanding for a total of 2.7 million square feet and 3,000 employees. It is the largest manufacturing plant under one roof in the Southeast.

Employees: About 3,000

Estimated 2016 Payroll: $160 million

Factoid: In eight short years, Engineered Floors has become one of the big three in floor covering in the U.S., joining Shaw Industries and Mohawk Industries, both of which have large operations in Dalton, Ga.

Economies Transformed: All of Northwest Georgia, specifically Dalton, Ga.

Boeing North Charleston, S.C.

Following a strike of 25,000 Boeing union workers at its primary assembly operations in Washington State, Boeing picked South Carolina for a non-union assembly campus in 2010.

Following a strike of 25,000 Boeing union workers at its primary assembly operations in Washington State, Boeing picked South Carolina for a non-union assembly campus in 2010.

Employees: About 7,600

Estimated 2016 Payroll: $570 million

Factoid: Boeing South Carolina began in 2004 as two companies — Vought Aircraft and Global Aeronautica. Boeing purchased both companies to create the 787 Dreamliner program in South Carolina.

Economies Transformed: Much of the Low Country in South Carolina. With Boeing, Daimler Vans and Volvo, the Charleston region of the state is hip-deep in big buffalo projects.

ZF Transmissions Laurens County, S.C.

There are many large automotive parts supplier employers in the Southern Auto Corridor and ZF Transmissions in Gray Court, S.C., is certainly one of them. ZF produces eight- and nine-speed automotive transmissions for passenger cars at the site in the Upstate. The German drivetrain manufacturer has spent over $600 million on the facility near Greenville. The 1.4 million-square-foot plant houses nearly 2,600 workers and can produce 1.3 million transmissions per year.

There are many large automotive parts supplier employers in the Southern Auto Corridor and ZF Transmissions in Gray Court, S.C., is certainly one of them. ZF produces eight- and nine-speed automotive transmissions for passenger cars at the site in the Upstate. The German drivetrain manufacturer has spent over $600 million on the facility near Greenville. The 1.4 million-square-foot plant houses nearly 2,600 workers and can produce 1.3 million transmissions per year.

Employees: About 2,600

Estimated 2016 Payroll: $138 million

Factoid: ZF manufactures the world’s first nine-speed automotive transmission at the Laurens County facility.

Economies Transformed: Laurens County, S.C., and the southern portion of the Upstate region.

Airbus Mobile, Ala.

With Alabama’s capture of the Airbus U.S. Manufacturing Facility — the company’s first production site in America — and Boeing’s South Carolina plant, the South became the home of two of the three final assembly jetliner plants in the United States. Airbus delivered its first A321 aircraft to JetBlue in April 2016. It has since built and delivered over 50 aircraft, mostly to U.S.-based airlines. The $600 million, 53-acre facility at the Mobile Aeroplex at Brookley will get a boost from a new partnership between Airbus and Bombardier. While nothing is confirmed as of yet, it looks like Airbus will build Bombardier’s C Series aircraft at the plant in Mobile.

With Alabama’s capture of the Airbus U.S. Manufacturing Facility — the company’s first production site in America — and Boeing’s South Carolina plant, the South became the home of two of the three final assembly jetliner plants in the United States. Airbus delivered its first A321 aircraft to JetBlue in April 2016. It has since built and delivered over 50 aircraft, mostly to U.S.-based airlines. The $600 million, 53-acre facility at the Mobile Aeroplex at Brookley will get a boost from a new partnership between Airbus and Bombardier. While nothing is confirmed as of yet, it looks like Airbus will build Bombardier’s C Series aircraft at the plant in Mobile.

Employees: About 510

Estimated 2016 Payroll: $35 million

Factoid: Ships from Europe sail into Mobile Bay several times a month carrying large parts of the A320 aircraft, some already painted for the customer. The vertical stabilizer is made in Spain, the wings from Wales, and the fuselages are made in France and Germany. Workers at the Airbus facility in Mobile then fully assemble the aircraft.

Economies Transformed: Much of South Alabama, including Mobile and Baldwin counties.

Big River Steel Osceola, Ark.

Big River Steel’s “flex mill” carries on a long line of steel and pipe plants in Mississippi County, Ark., all of which are located on the Mississippi River. Big River joins Nucor-Yamato, Nucor, Tenaris, IPSCO and Atlas, making this area a large manufacturing cluster of nearly 5,000 workers in a county with just 44,000 residents.

Big River Steel’s “flex mill” carries on a long line of steel and pipe plants in Mississippi County, Ark., all of which are located on the Mississippi River. Big River joins Nucor-Yamato, Nucor, Tenaris, IPSCO and Atlas, making this area a large manufacturing cluster of nearly 5,000 workers in a county with just 44,000 residents.

Employees: About 500

Estimated 2016 Payroll: $40 million

Factoid: Big River Steel is the world’s first smart steel production facility. The plant is equipped with artificial intelligence systems to optimize maintenance planning, line scheduling, logistics and environmental protection.

Economies Transformed: Mississippi County, Ark., and much of the Delta of Northeast Arkansas and West Tennessee.