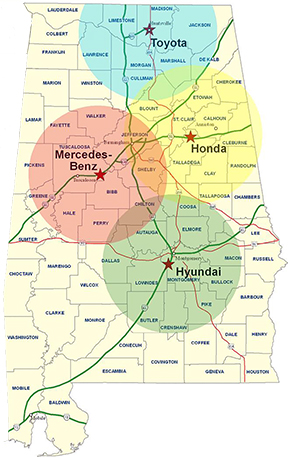

Alabama’s four assembly plants and affiliated factories contributed $10.8 billion to the state’s economy last year. That’s according to a new report from Autos Drive America and the American International Automobile Dealers Association (AIADA). According to the report, the auto industry has invested $14.5 billion in Alabama. Last year, Mercedes-Benz, Honda, Hyundai and Mazda-Toyota produced 1.124 million vehicles, with $10.7 billion in autos purchased from U.S. suppliers. As far as jobs, the industry created 88,947 total jobs, generating $6.4 billion in total compensation. That includes more than 17,000 direct jobs and 64,000 indirect jobs. According to the report, every direct auto-making job supports 3.5 additional jobs in Alabama. In revenue, the industry generated $892 million in state and local taxes, and $1.5 billion in federal tax receipts.

Governor Kay Ivey announced that Alabama is building a $30 million workforce training center in Decatur that will focus on electric vehicles and emerging technologies in order to position the state’s auto industry for the next chapter of its growth. The facility will be located on the campus of the Alabama Robotics Technology Park, a unique $73 million center operated by AIDT that helps companies train workers on advanced R&D and manufacturing technologies.

Alabama Commerce Secretary Ellen McNair joined officials of Samkee Corp. and local leaders last quarter to mark the opening of the auto parts maker’s new production facility in Tuskegee Commerce Park. South Korea-based Samkee invested $128 million to build its first U.S. factory, which will employ over 170 people at full operation while providing a massive economic boost for rural Macon County.

“Samkee is a first-class addition to Alabama’s dynamic auto industry, and the opening of this state-of-the-art facility in Tuskegee demonstrates that the industry continues to gain horsepower in the state,” Commerce Secretary McNair said about the manufacturer of die-cast components for the automotive sector.

Shape Corp., a global Tier 1 automotive supplier, officially opened its second Alabama production facility after completing a $74 million growth project that will create over 100 jobs in the coming year. Michigan-based Shape Corp., which opened a plant in nearby Athens, Ala., in 2016, held a ribbon-cutting ceremony at the new 202,306-square-foot facility in Southpoint Industrial Park. “This new facility represents our ongoing commitment to innovation and excellence in the automotive industry,” said Mark White, president and CEO of Shape Corp. “By expanding our operations in Alabama, we are not only increasing our production capabilities, but also investing in the local community through job creation and economic growth.”

Auto parts maker Daewon is planning a $46.2 million expansion in Opelika, Ala., that will create 100 jobs. John Sweatman, the city’s economic development director, said Daewon has made $164 million in capital investments in Opelika since the company came to the city in 2006.

Electric vehicle manufacturer Canoo Technologies announced in November 2021 that it was moving its corporate headquarters from Texas to Bentonville, Ark., and planning a research and technology center in Fayetteville. That is unlikely to happen now as the warehouse in Bentonville where Canoo was to begin EV assembly is now up for sublease, after only a couple of years of the company signing a 10-year lease. But Canoo never moved in because it could not secure, according to the company, a second site in the area to house its headquarters.

A couple of decades ago, Toyota and its site selection guru, Dennis Cuneo, scouted a megasite across the bridge from Memphis in Marion, Ark., to build a large assembly plant. That was the pickup truck project that ended up in San Antonio. While East Arkansas lost out on that deal, they gave the Delta a “parting gift,” according to workforce development pro, Dr. Glen Fenter. (Fenter is the superintendent of Marion, Ark. Schools.) The parting gift was Hino, which makes stamping and component parts in Marion. In June, the Japanese-based parts manufacturer announced it will close the 1,300-employee facility in late 2027. HMM is a subsidiary of Japanese publicly traded company Hino Motors Ltd., of which Toyota owns a majority stake. HMM began production at its Marion facility in 2006, and has expanded multiple times over the years.

Korean automaker Hyundai is well into hiring at its metaplant just west of Savannah. The plant is nearing completion and test vehicle assembly has started. Hyundai’s facility is reshaping the Savannah area’s labor landscape. The assembly plant and adjacent battery factory, located 25 miles west of downtown Savannah near Ellabell, will employ 8,500 at full build-out, while suppliers put 7,000 more residents to work.

Rivian Automotive landed a major investment that may get its Georgia plant back on track. The EV startup has joined with Volkswagen to fund its prospective plant east of Atlanta. Rivian could help the German automotive company expand its plans for software-defined vehicles based on Rivian’s existing software platform, electrical architecture and technical capabilities. Rivian originally planned to manufacture the R2 SUV at its new Georgia facility, but has since decided to move production to Normal, Ill. The first R2s are expected to roll off the assembly line in the first half of 2026.

Ford considers new $400 million plant Shelby County

Ford considers new $400 million plant Shelby CountyFord Motor Co. appears to be considering a site in Shelby County for a small, specialized EV component plant. The plant was mentioned during a recent meeting of the Kentucky Economic Development Finance Authority. It was referenced in meeting minutes and the Courier Journal reports. Gov. Andy Beshear has confirmed it as well. The project would be an investment of $400 million, according to the meeting minutes, all of which qualifies as eligible for tax incentives for the Kentucky Business Incentive program — a state program that gives companies tax breaks on major projects.

Another portion, $170 million, would qualify for incentives under the state’s KEIA program, which provides a refund of Kentucky sales and use tax. According to the minutes, the project would create 260 jobs with an average wage of $36 per hour, including benefits.

Louisville Business First

Element 25, an Australian mining company, has purchased a 35-acre site in Ascension Parish, where it hopes to invest $289 million in a plant to make electric battery components. The plant would be the first in the Western Hemisphere to manufacture high-purity manganese sulphate monohydrate, or HPMSM, a critical component in electric vehicle batteries.

BlueOval City, a massive Ford-driven project north of Memphis, is nearing completion. Ford will manufacture its next-generation electric truck at BlueOval City, which is scheduled for completion this year. Kel Kearns, formerly the plant manager at the Tennessee Electric Vehicle Center at BlueOval City, will serve as CEO of Amplify Cell Technologies, the name for the tri-venture between Cummins, Daimler Truck and Paccar. The nearly $2 billion facility will produce differentiated lithium-iron-phosphate (LFP) battery cells in Marshall County, Miss. The North Mississippi plant is projected to house 2,000 workers.

Governor calls North Carolina the “epicenter of clean energy”

Governor calls North Carolina the “epicenter of clean energy” In the summer quarter, North Carolina Gov. Roy Cooper said that the Tar Heel State is the center of clean energy. From the Triad Business Journal: “If you talk to any CEO of any car company in the world, they will tell you that they are stumbling all over themselves to get into the market first for affordable vehicles,” says Governor Roy Cooper.

Toyota is building its $13.9 billion battery manufacturing plant in Randolph County, N.C., (near Greensboro). In the meantime, Vietnamese EV maker VinFast has delayed constructing the first electric vehicle manufacturing facility in the Triangle Region in Chatham County for three years. That project is fueled in part by a $1.2 billion economic development initiative, largest in the state’s history. Toyota’s project will create more than 5,000 jobs upon completion in 2025.

The Triad Business Journal also contained a quote from the president of Toyota Battery Manufacturing: “The thing that we were really, really interested in, and we felt like we can capitalize on, was the human capital in the people, the talent pool that they had here, mainly driven a lot by their school systems, their college systems,” said Sean Suggs, North Carolina president of Toyota Battery Manufacturing.

Small EV maker to create jobs in South Carolina

Small EV maker to create jobs in South CarolinaThe Columbia Vehicle Group, an electric vehicle manufacturer, announced it selects Aiken County for the company’s first South Carolina operation. The company’s $12.2 million investment will create 180 new jobs. Part of the Nordic Group of Companies, Columbia Vehicle Group manufactures pure electric vehicles for industrial and commercial markets under the Columbia and Tomberlin brands. The company’s products, which include golf carts, utility vehicles, maintenance vehicles and e-bikes, are distributed globally. Columbia is relocating manufacturing operations from Florida and Wisconsin to Aiken County for closer proximity to customers and its supply chain. The company will purchase and up-fit an existing 154,480-square-foot facility located on University Parkway in Aiken.

Ford Motor Co. made a major announcement in the summer regarding its BlueOval City plant north of Memphis. Mass hiring for BlueOval City was scheduled to start next year. Then, Ford made the decision this summer to delay the production of its F-150 EV pickup truck line until 2027. The project was announced in 2021 and was originally scheduled to be completed in 2025. However, much of the massive complex is complete with robotic training cells, conveyors, paint spray booths, and stamping press lines have been installed at what is called the Tennessee Electric Vehicle Center (TEVC) in rural Stanton, Tenn.

UAW successfully organizes union at VW plant in Chattanooga

UAW successfully organizes union at VW plant in ChattanoogaIn the spring, workers at a Volkswagen plant in Tennessee voted to join the union, the first large non-union auto plant in the South to do so. Weeks later, the union negotiated a new contract bringing significant pay and benefit improvements for its members at several North Carolina factories owned by Daimler Truck. And in the summer, 5,000 Mercedes-Benz employees at its plant in Tuscaloosa, Ala., defeated UAW organization.

Local officials are hopeful that nearly $32 million in public incentives will sway Toyota to invest more than $531 million in a major expansion of its San Antonio manufacturing campus. Last month, Bexar County Commissioners authorized negotiations with Toyota on an incentives package valued at $14.9 million. Commissioners have now approved a contract between the county and Toyota tied to those incentives.