Alabama’s mining and manufacturing strength is historic and it all started in Birmingham, which sits in Jones Valley, the one and only place in the world where all three ingredients to make iron and steel — iron ore, limestone and coal — are found. Because of its mineral-rich location, Birmingham was the South’s foremost industrial hub in the early 20th century. Immigrants, migrants, farmers, sharecroppers. . .you name it. . .were lured to work in the steel mills in and around Birmingham because of the high pay.

Alabama’s mining and manufacturing strength is historic and it all started in Birmingham, which sits in Jones Valley, the one and only place in the world where all three ingredients to make iron and steel — iron ore, limestone and coal — are found. Because of its mineral-rich location, Birmingham was the South’s foremost industrial hub in the early 20th century. Immigrants, migrants, farmers, sharecroppers. . .you name it. . .were lured to work in the steel mills in and around Birmingham because of the high pay.

So many large steel mills opened in the early 1900s, such as long closed facilities like Sloss Furnace and the massive Ensley works, that Birmingham was called “The Pittsburgh of the South.” During World War II, Birmingham steel mills played a key role in providing steel in the war effort. U.S. Steel is the best known steel factory left in the area and it is growing again after decades-long, up-and-down financial periods. However there were, and still are, plenty of other metals plants in the area, such as Charlotte-based Nucor.

So many large steel mills opened in the early 1900s, such as long closed facilities like Sloss Furnace and the massive Ensley works, that Birmingham was called “The Pittsburgh of the South.” During World War II, Birmingham steel mills played a key role in providing steel in the war effort. U.S. Steel is the best known steel factory left in the area and it is growing again after decades-long, up-and-down financial periods. However there were, and still are, plenty of other metals plants in the area, such as Charlotte-based Nucor.

Fast forward to today and Alabama is again a manufacturing juggernaut, much like when it first burst on the scene in the early 1900s. With the completion of the Mazda Toyota plant in Huntsville this year, Alabama will become the second state in the Southern Automotive Corridor with four major automotive assembly plants. Toyota also operates a very large engine plant in Huntsville, and Honda and Hyundai have engine plants on site of their assembly plants in Lincoln, Ala., and in Montgomery.

Fast forward to today and Alabama is again a manufacturing juggernaut, much like when it first burst on the scene in the early 1900s. With the completion of the Mazda Toyota plant in Huntsville this year, Alabama will become the second state in the Southern Automotive Corridor with four major automotive assembly plants. Toyota also operates a very large engine plant in Huntsville, and Honda and Hyundai have engine plants on site of their assembly plants in Lincoln, Ala., and in Montgomery.

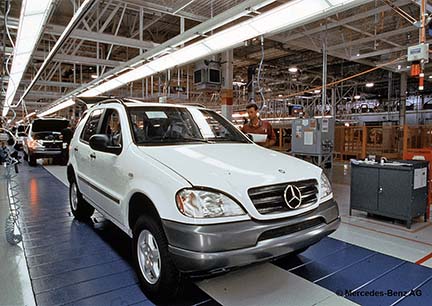

The other three automakers in Alabama are Mercedes-Benz, Honda and Hyundai. There are over 40,000 people working in the automotive industry in the state, and over 165 parts suppliers. Those totals will see a significant increase once Mazda Toyota Manufacturing USA opens its joint venture plant in Huntsville. The $2 billion plant will house as many as 4,000 workers, and multiple suppliers on site and near the plant are hiring now. The investment and the total announced workforce of 4,000 is the largest single greenfield automotive deal in Southern Auto Corridor history.

Before Mercedes-Benz announced its plant in Tuscaloosa County in 1993, there were few automotive-based outfits in the state supplying assembly plants out of state. Today, 28 years after Mercedes-Benz announced its only plant in the U.S. in Vance, Ala., the state is in the top five in automotive production in the U.S. every year.

Before Mercedes-Benz announced its plant in Tuscaloosa County in 1993, there were few automotive-based outfits in the state supplying assembly plants out of state. Today, 28 years after Mercedes-Benz announced its only plant in the U.S. in Vance, Ala., the state is in the top five in automotive production in the U.S. every year.

The other state in the Southern Auto Corridor with four major assembly plants is Kentucky. Two Ford plants, a GM plant and a Toyota plant are located and operational in the Blue Grass State.

Alabama-made vehicles have become the state’s No. 1 export to over 90 nations, with the state’s largest export customers being China and Germany (home to the Mercedes-Benz headquarters). Automotive, in short, is an incredibly important part of the state’s economy, and production has only been in play in the state for 25 years. The foreign-only-automaker plants in Alabama will most likely still be producing vehicles at the turn of the next century.

While automotive is a huge segment of the manufacturing arena for the state of Alabama, its prowess as one of the South’s most important manufacturing hubs stems from so much more than automotive. For example, there are only three final assembly plants for jetliners in the U.S., and the South has two of them — Boeing in North Charleston, S.C., and Airbus in Mobile, Ala.

Airbus, the European-based jetliner manufacturer, has recently finished up its expansion in Mobile, Ala., where it added another line to its A320 family of commercial aircraft. The new line has added the A220 commercial aircraft, an endeavor that has doubled the size of the Airbus facility located at the former Brookley Air Force Base on the shores of Mobile Bay.

Airbus, the European-based jetliner manufacturer, has recently finished up its expansion in Mobile, Ala., where it added another line to its A320 family of commercial aircraft. The new line has added the A220 commercial aircraft, an endeavor that has doubled the size of the Airbus facility located at the former Brookley Air Force Base on the shores of Mobile Bay.

Alabama’s aerospace industry is a mile wide and a mile deep. In addition to Airbus, major aerospace companies operate, in some cases, multiple major facilities in Alabama — GE Aviation, Lockheed Martin, Boeing, Raytheon, GKN Aerospace and Collins Aerospace to name a few of the more than 300 aerospace companies that call Alabama home. All told, aerospace manufacturing employs about 14,000 in the state. Aerospace engineers total over 4,000 in Alabama, which ranks the state in the top in the U.S.

In January of 2021, the Air Force and the Pentagon chose Huntsville as the future site of the U.S. Space Command’s headquarters. (That headquarters currently is at Peterson Air Force Base in Colorado Springs, Colo.) Huntsville’s Redstone Arsenal was one of six finalists for the Space Command. The U.S. Space Command was established during the Trump administration as the 11th combatant command. The project is expected to initially create 1,400 jobs and add to the 62,000 aerospace and defense jobs in Alabama.

Immediately after the decision to establish the Command in Huntsville was made, there was opposition from several politicians in the other states that made the final six — Texas, California, Colorado, New Mexico and Nebraska.

Officials in those states that were in the running for the Space Command argued that the final decision to locate the facility was politically motivated. They claim that Alabama was chosen under the Trump administration because the former president lost Colorado in the presidential election and won Alabama.

Whatever happened regarding the Space Command site search, Huntsville is the perfect place for it. The Air Force claims the decision was based on a grading system in which Huntsville’s Redstone Arsenal beat Colorado in 11 of 21 comparisons, including qualified workforce, quality schools, infrastructure capacity and cost-of-living factors.

Huntsville’s Redstone Arsenal is home to the Army Aviation and Missile Command, the Army’s Space and Missile Defense Command and the Army Strategic Forces Command. Huntsville is also home to hundreds of defense contractors and space industry facilities, including the Marshall Space Flight Center, one of NASA’s largest operations.

Redstone doubles as a large military base. Activity at the base includes military missile operations and space-related military and civilian operations. Redstone has been linked to space flight since Day One, when the first U.S. satellite was launched in the space race with the Soviet Union.

Alabama’s comprehensive aerospace/aviation presence also includes an extensive roster of training programs and assets. AIDT’s Robotics Technology Park near Decatur offers specialized training in robotics and automation programs, and AIDT operates an aviation training center in Mobile. In addition, the Alabama Community College System’s Alabama Aviation Center, which has several locations across the state, offers FAA-certified training in airframe and engine maintenance.

Auburn, Ala.

SiO2 Materials Science increased its production capacity to meet the U.S. government’s critical need for vials and syringes while maintaining the existing production needs of other customers, including pharmaceutical companies.

In June 2020, SiO2 announced a $143 million contract with federal government agencies for a production scale-up of the company’s state-of-the-art packaging platform for storing novel coronavirus (SARS-CoV-2) vaccines and therapeutics.

A key element of SiO2’s product is enhanced safety for healthcare providers and for patients who are at a lower risk of adverse side effects. A combination of plastic and a microscopic layer of glass also means vials and syringes won’t break, shatter or crack. SiO2 ships its products worldwide.