After the worst year of vehicle sales in more than a decade, automakers in the Southern Automotive Corridor are optimistic that 2023 will be a rebound year. Industry experts believe vehicle sales in the U.S. were near 14 million in 2022, an 8 to 9 percent drop from 2021. Parts and supply chain issues affected many automakers in 2022.

Mazda not yet at “full employment” at Alabama plant

Mazda not yet at “full employment” at Alabama plant

Back in the year 2018, Mazda and Toyota announced a joint-venture plant in Limestone County, Ala. The plant currently houses 3,700 employees, but the two Japanese automakers are having a tough time reaching the goal of 4,000 workers as a result of thin labor pools and retention issues. Mazda makes its CX-50 crossover model at the plant and Toyota its Corolla Cross model.

Hyundai Mobis plans EV battery module plant in Montgomery

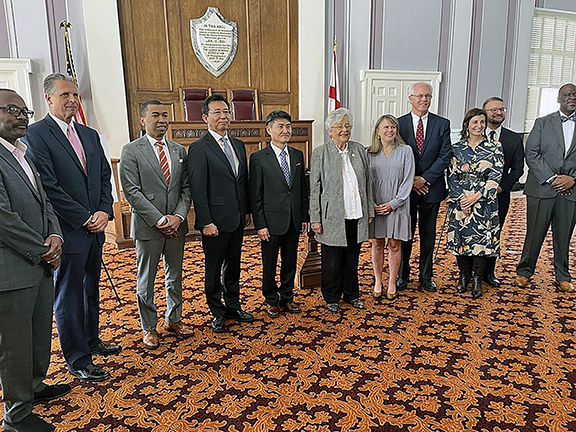

In the fall quarter, Gov. Kay Ivey joined executives of Hyundai Mobis, one of the world’s largest auto suppliers, to announce the company’s plans to invest $205 million to open an EV battery module plant in Montgomery that will eventually employ at least 400 people. Once it reaches full production, the 450,000-square-foot facility will be able to supply over 200,000 EV batteries annually to the Hyundai Motor Manufacturing Alabama (HMMA) factory in Montgomery and the Kia Georgia plant in West Point, Ga.

Hyundai and SK On announce $4 billion EV battery deal in Georgia

Hyundai and SK On announce $4 billion EV battery deal in Georgia

Gov. Brian P. Kemp announced in December that Hyundai Motor Group (HMG) and SK On have selected a site in Bartow County, Ga., for a new electric vehicle (EV) battery manufacturing facility that will supply Hyundai Motor Group’s plants in the U.S. One of the largest economic development projects in state history, stakeholders estimate it will create more than 3,500 new jobs through approximately $4 billion to $5 billion of investment in Bartow County. Hyundai Motor Group and SK On recently signed a memorandum of understanding (MOU) regarding the partnership for a new EV battery facility in the U.S., with the details of the partnership still in development.

New supplier to Hyundai’s massive Georgia EV plant

Hyundai Mobis, one of the world’s largest automotive suppliers, plans to invest $926 million in a new facility in Bryan County, Ga. The plant will help supply electric vehicle production at Hyundai’s new multi-billion-dollar, multi-thousand-job complex in Southeast Georgia. The deal will create 1,500 jobs.

Another EV battery maker announces billion-dollar-plus investment

FREYR Battery, a developer of clean, next-generation battery cell production capacity, will invest $2.57 billion into Georgia’s sustainable technology ecosystem and create 723 new jobs over the next seven years at a manufacturing facility in Coweta County.

First Georgia Hyundai supplier to build new facility in Georgia

Joon Georgia Inc., an automotive parts manufacturer, will create 630 new jobs and invest $317 million in Bulloch County. Plans for the company’s new manufacturing facility mark the first confirmed supplier for Hyundai Motor Group Metaplant America in Bryan County.

Hyundai execs and Gov. Kemp break ground on Georgia megasite

Governor Brian P. Kemp, along with Hyundai Motor Group (HMG) Executive Chair Euisun Chung and company officials, officially broke ground on Hyundai Motor Group Metaplant America’s (HMGMA) new manufacturing plant at the Bryan County Megasite, The $5.54 billion investment for this facility by the company and its affiliate suppliers was announced in May of last year and includes plans to produce a diverse range of innovative, fully electric vehicles (EV) and a new battery manufacturing facility. HMGMA will create more than 8,100 jobs over the next few years as the company establishes a stable supply chain for EV battery and associated components in the U.S. market.

Kentucky’s largest-ever economic development project going up

Kentucky’s largest-ever economic development project going up

At the Glendale Megasite on Interstate 65 in Kentucky, Ford and its South Korean partner, SK, are building a pair of manufacturing plants that will produce batteries for Ford and Lincoln electric vehicles. Construction has been going on for quite a while now on the multi-billion-dollar project, yet, the official groundbreaking took place in December. The 2.3-square-mile campus will eventually employ 5,000 workers.

Vietnamese electric vehicle manufacturer goes public because of new North Carolina assembly plant

VinFast, which is building a $2 billion electric vehicle and battery plant in North Carolina, has filed a registration statement with the U.S. Securities and Exchange Commission, the first formal step toward a public offering this year. The company became Vietnam’s first automaker in 2019.

Electric vehicle manufacturer to open facility in OKC

Following a long line of electric vehicle and battery announcements in the Southern Automotive Corridor (go to SouthernAutoCorridor.com), Canoo announced in the fall it will locate an assembly facility in Oklahoma City. The project is expected to generate 500 jobs and 20,000 units by the end of 2023.

Huge deal in the South Carolina Low Country

Redwood Materials is locating its next Battery Materials Campus in the heart of the “Battery Belt,” just outside of Charleston, S.C. The facility will be built at Camp Hall in Berkeley County. Redwood will recycle, refine and manufacture anode and cathode components on more than 600 acres, creating more than 1,500 jobs and investing $3.5 billion in the local community. The company combines recycling, refining and re-manufacturing to produce and return battery materials to U.S. battery cell manufacturers used in electric vehicles.

Ultium Cells to expand Tennessee facility

Ultium Cells to expand Tennessee facility

Ultium Cells, a joint venture of LG Energy Solution and General Motors, will expand its Spring Hill, Tenn., battery cell manufacturing operations. The project represents a $275 million investment by Ultium Cells, which is in addition to the $2.3 billion investment announced in April 2021, and is expected to create 400 additional jobs. Once the facility is fully operational, Ultium Cells is expected to employ a workforce of 1,700 in Maury County.

Ultium Cells will increase battery cell production by more than 40 percent, from 35 gigawatt hours to 50 gigawatt hours. The Tennessee facility will supply battery cells to General Motors’ Spring Hill assembly plant for production of the Cadillac LYRIQ, the first electric vehicle produced at the plant, and other GM Ultium Platform-based electric vehicles. Production at the 2.8-million-square-foot facility will begin in late 2023.

Single largest foreign direct investment in Tennessee history announced

LG Chem announced in December a $3.2 billion cathode manufacturing facility in Clarksville, Tenn. It is part of the massive electric vehicle supply chain that is remaking much of the American South’s economy.

Tesla’s Austin factory delivers first electric semi-truck

In the winter quarter, Austin-based Tesla delivered its first electric semi-truck to its first customer, PepsiCo. The delivery is the first since Tesla CEO Elon Musk said his company would start making the trucks.